Milling Machine Test

/Last night I decided to test the milling machine with a simple 1 inch square and a 3/8ths on an inch circular pocket (hole). Since I didn’t feel like setting up a machining vise and aligning it, I used a trick that I’ve seen on ClickSpring on YouTube and NYC CNC: superglue and painters tape.

Keep in mind this was simply just to see if the ballscrew calculations were correct (I changed the number slightly from the previous post since the steppers I have only have two points). My goal was to machine the square and measure how close to 1 inch it actually would be. I was hoping to be within 0.001”.

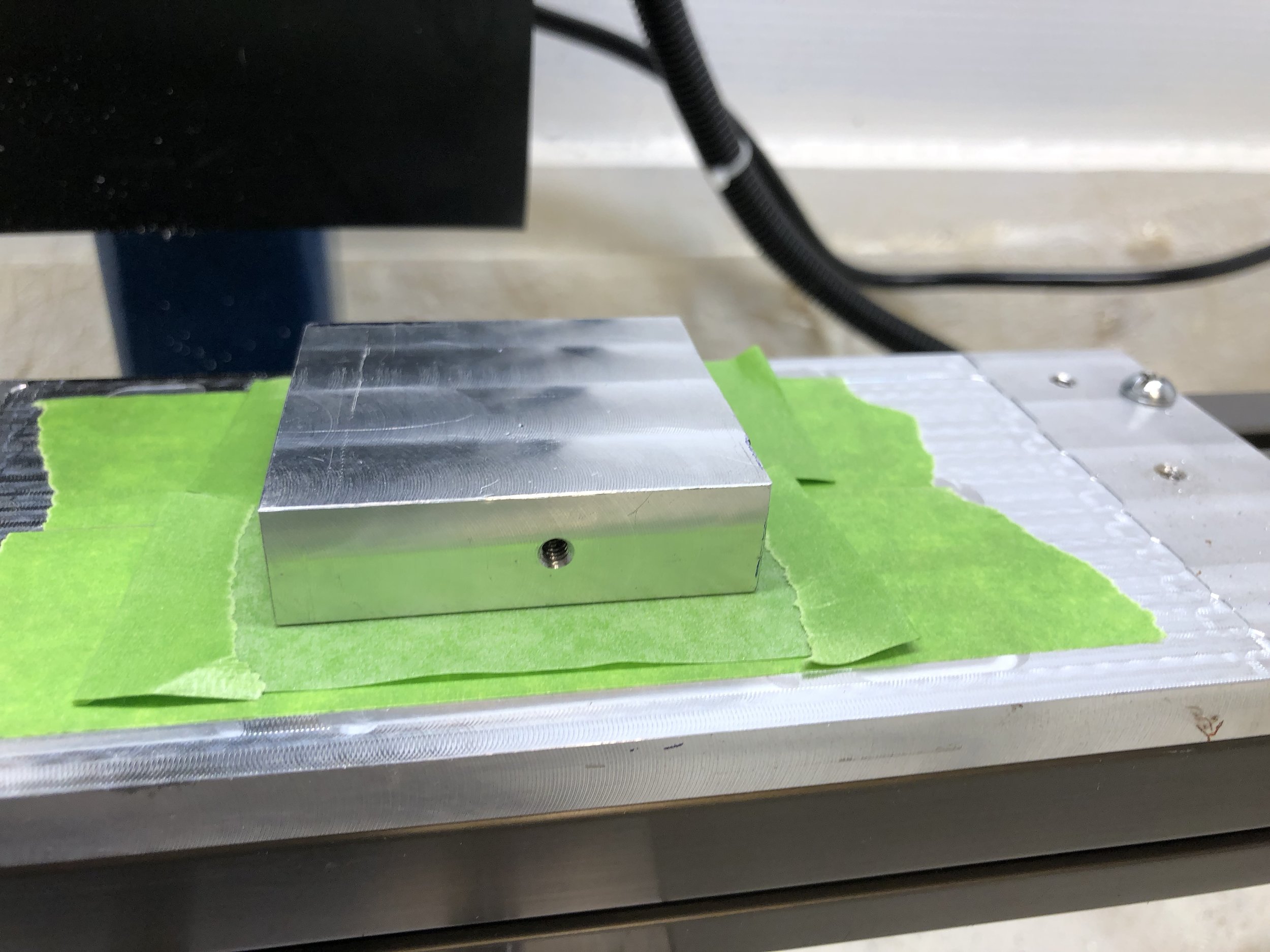

The idea of using superglue allows quick stock placement and strong work holding. I began by placing an aluminum plate on the mill table and machined it to be flat and smooth. Then, I placed painters tape down to make a surface to place superglue.

Based on John Saunders of NYC CNC, I chose Frogtape due to increased strength over 3M Blue. The next step was to place tape on the raw stock (I had already machined it flat, too). Finally, you apply superglue to the part and apply pressure to secure it to the fixture plate.

Now, it should have gone smoothly and completed in about 20 minutes. I didn’t really do much work to ensure proper tool speed, but it did hold perfectly. Aside from the loud chatter, probably due to no support in the middle of the aluminum plate, it was perfect. Until...

For some reason, my CNC software decided it wanted to stop near the very end of machining the square. I had enough space to test the square dimension, but never got to the circular pocket.

Albeit frustrating, I was happy to measure it and get far better than expected. But there was one issue: I forgot to machine a relief hole to easily remove the part that was superglued. Oh well, a heat gun will help burn away the superglue.

Now, I can begin machining roller coaster parts. I’m going to start with forms to build ride structure. Be on the lookout on the YouTube channel for more updates!